CAPO Test

Instrument Details

Make : Germann Instruments, Denmark

Model : 030613

Specification : Estimation of compressive strength in existing structure

The Cut and Pull Out (CAPO) is a reliable test method to determine the in-situ compressive strength of concrete. The groove is recessed through the center hole by a diamond tool with a similar shape as a dentist's drill, larger at the tip than at the base. The CAPO test results are found to be within 8% of the results obtained from conventional methods. The CAPO tests determines the compressive strength of in-situ concrete in various structures like concrete Roads, bridges, buildings etc.

Working Principles

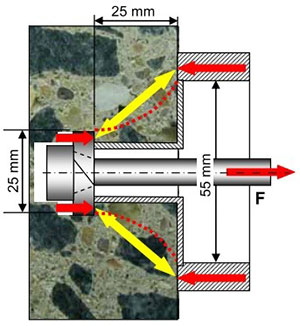

When selecting the location for a CAPO-TEST, ensure that reinforcing bars are not within the failure region. The surface at the test location is ground using a planning tool and a 18.4 mm hole is made perpendicular to the surface using a diamond-studded core bit. A recess (slot) is routed in the hole to a diameter of 25 mm and at a depth of 25 mm. A split ring is expanded in the recess and pulled out using a pull machine reacting against a 55 mm diameter counter pressure ring. As in the LOKTEST, the concrete in the strut between the expanded ring and the counter pressure ring is in compression. Hence, the ultimate pullout force F is related directly to compressive strength. The test is performed until the conic frustum between the expanded ring and the inner diameter of the counter pressure is dislodged. Thus there is minor surface damage, which should be repaired for aesthetic reasons or to avoid potential durability problems.

Applications

- Quality assurance testing of the finished structure

- Verification of in-place strength if strength of standard-cured specimens fails to meet acceptance criteria

- Estimating strength of concrete in existing structures

- Evaluation of fire-damaged structures

User Instructions

- Testing location should not select over reinforcement mesh.

- During center hole coring drill machine should be axially & core to half depth, remove it and continue drilling to full depth.

- Testing surface should be planned axially.

- Routing of the recess carefully.

- During the expansion of capo-Inserts, flush with water to remove left-over particals inside the hole.

- Counter pressure and coupling installed & make sure three small pins of the coupling are pointing towards the concrete.

- The Capo-Test hydraulic pull-machine should be rotated anti-clockwise 39 rotations to fully extended position.

Contact Details

HEAD, RIGID PAVEMENT DIVISION

CSIR-CENTRAL ROAD RESEARCH INSTITUTE

Delhi-Mathura Road

P.O: CRRI, New Delhi-110025

Telephone: 011-26310734

Email Id: director [dot] crri [at] nic [dot] in

Instrument Usage Charges (Including GST)

|

Tests |

Industry |

University |

National Lab/R&D |

Remarks |

|---|---|---|---|---|

|

Compressive Strength in existing structure |

30,000/- |

20,000/- |

20,000/- |

Per Samples |